[[{“value”:”

Reaching climate neutrality in operations by 2030 is an ambitious goal, yet Unic and its parent company Electrolux Professional Group are charging towards their target.

Electrolux Professional Group is serious about sustainability. The global food service, beverage, and laundry solutions provider aims to achieve climate neutrality – in which companies reach net-zero greenhouse gas emissions by balancing emissions with removals – in the next five years. It’s not an easy feat for any company, let alone one that works in 110 countries and employs 4300 people.

“At Electrolux Professional Group, we want to do our part to improve society and generate value for our stakeholders. We have considered the external challenges the world is facing and assessed what we can do to help overcome these hurdles,” says Swapnil Choudhari, Electrolux Professional Group VP Sustainability & Quality.

To help reach this target, Electrolux Professional Group has set itself six sustainable development goals (SDGs), which cover areas including clean and affordable energy, climate action, decent work and economic growth, responsible consumption and production, clean water, and gender equality. Choudhari says these goals are avenues through which the company can have a meaningful impact and provide an opportunity to make a difference.

“These SDGs guide our sustainability strategy. This goes hand in hand with our company mission to make our customers’ work life easier, more profitable, and truly sustainable,” he says.

As part of its SDGs in clean energy and climate action, Electrolux Professional Group is developing energy efficient products as well as improving the energy efficiency of its own operations.

“We continue investing in increasing the renewable electricity share at our manufacturing sites while also improving the efficiency of our plants to reduce energy demands. Since 2019, we have already reduced our Scope 1 and 2 emissions by 61 per cent,” says Choudhari.

“We also have a major focus on developing sustainable products for our customers. We do that by ensuring we innovate products that consume less energy, water, and detergent as well as using materials efficiently to reduce the impact caused throughout our value chain.”

Electrolux Professional

Group VP Sustainability

& Quality. Image: UNIC.

Unic, Electrolux Professional Group’s commercial espresso machine brand, has fully embraced this focus on energy reduction. Its research and development team have integrated a structured and sustainable approach into all stages of new product development and technological innovation, which has resulted in some of the most energy efficient products on the market.

Jeremy Coquille, Research and Development Manager of Unic, says the team’s main objective when designing a new product is ensuring it has less impact on the planet than its predecessor.

“We start by thinking how we can produce a product in a better way and reduce its energy consumption,” says Coquille.

“A major focus is the raw materials used to build the espresso machine. Creating a machine that’s highly recyclable is fundamental – we no longer use a material that cannot be recycled.”

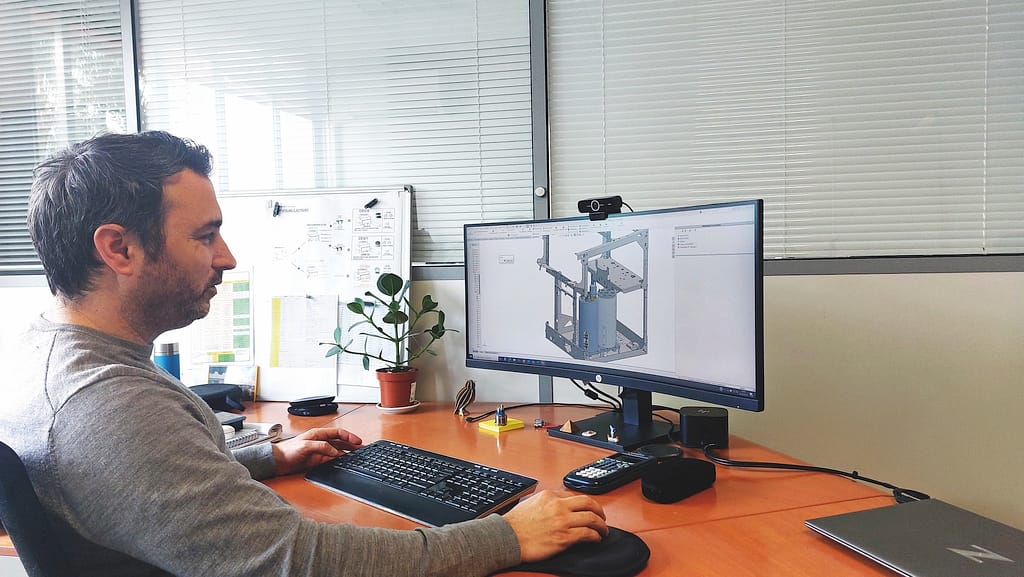

In addition, the team use 3D modelling analysis to improve the design of the machine’s components to reduce the quantity of the material used while achieving the same functionality. An example is the latest Tango XP super automatic espresso machine, which is 42 kilograms lighter than the previous model. This not only decreases the amount of material used but also reduces transport emissions.

In the creation of the Tango XP, the design team also made a commitment to reduce the amount of chemicals used. This resulted in the machine’s unpainted casing.

“Previous models were painted with an epoxy coating. Painting the machines has a high energy demand, as the operator needs to be wearing strong protection, cleaning chemicals are required to clean the tools, and the epoxy coating needs to be set in an oven at a high temperature,” says Coquille.

“Instead of painting the machines, we swapped the casing and frame material to stainless steel, which doesn’t require a protective coating.”

At the end of the Tango XP’s life, the machine can be disassembled and fully recycled. What’s more, each machine features a sticker with the details of the service company that will collect the model, disassemble it, and ensure every component is recycled.

If spare parts or maintenance is required, Coquille and team have designed the machine in a smart modular manner so that small parts can be replaced without having to unnecessarily waste working components.

“At Unic, we have effectively utilised the concept of modularisation, surpassing many competitors in this regard. Our approach allows for easy machine repairability, enabling specific components to be replaced individually in the event of a failure. This means other components within the same module can still be reused,” he says.

Coquille believes Unic’s modular design facilitates more efficient maintenance, as service technicians can simply replace broken components rather than the entire module.

“For instance, many machines on the market today feature an all-in-one boiler that cannot be dismantled. If the heating element breaks, the entire boiler must be replaced,” he says.

“In contrast, our design allows the heating element to be replaced while the boiler module and other parts can still be reused, thereby reducing the strain on material resources.”

For the Tango XP boiler module, Coquille and team reduced its size, resulting in less energy needed to maintain the desired water temperature.

“For our next machine, we’re working on an AI system that will analyse the use of the machine and determine the trends around activity and peak demand,” he says.

“The machine will automatically adapt the energy use and regulation of the boiler according to the anticipated peaks across the day.”

In addition to the sustainability work taking place at Unic’s headquarters, the brand works with its long-standing clients to ensure they can reach their own sustainability goals. Cafés Richard, one of France’s leading coffee roasters serving 40,000 clients per year, has worked with Unic for more than 30 years. As part of its approach to corporate social responsibility, the coffee roaster has established a reconditioning program to extend the life of its espresso machines, with Unic acting as subcontractor.

Eric Duriez, Purchasing Director for Expresso Equipment and Service at Cafés Richard, says 15,200 machines were reconditioned as part of the program in 2024, including 450 Unic machines.

“Unic’s expertise in the design and manufacture of fully automatic Tango machines legitimises Unic in subcontracting the reconditioning of this type of equipment,” says Duriez.

The reconditioning program features six stages: collection, aesthetic quality control, workshop repair including replacement of worn parts, reconditioning, technical quality control, and finally installation at customer site.

A Reconditioned Machine logo is provided along with a box of accessories and cleaning tablets. A daily and weekly cleaning tutorial via QR code is also supplied to make users aware of the need for daily maintenance to guarantee the durability of their work equipment.

“By choosing reconditioned equipment, customers are working alongside Cafés Richard in a shared circular economy approach to achieve more sustainable growth,” says Duriez.

“They are also made aware of where the equipment is manufactured: with Unic, the ‘designed and made in France’ argument, attested by the Origine France Garantie certification of the machines, responds to the growing desire to operate in short circuits. It’s also worth noting that public authorities and major groups are becoming more aware of the issue and are now asking suppliers like Cafés Richard to include a proportion of reconditioned equipment in their tenders for new contracts.”

For more information, visit unic-espresso.com

This article was first published in the May/June 2025 edition of Global Coffee Report. Read more HERE.

The post Unic, Electrolux charging towards climate neutrality appeared first on Global Coffee Report.

“}]]