[[{“value”:”

BY JON FERGUSONSPECIAL TO BARISTA MAGAZINE

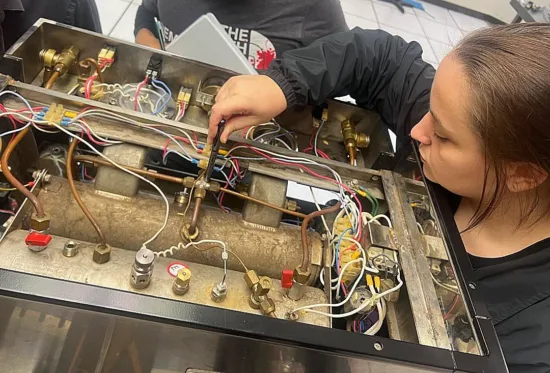

Photos courtesy of Hope Roberts

As a writer with personal service technician field experience, I always find it refreshing to see other service techs out in the field with solutions to the day-to-day challenges that come with communicating with your customers effectively. And whether you are the service tech or the shop owner, it is helpful to have both parties on the same page and mental headspace. Most of the time, service techs and their customers have the same goal in mind: Get the job done safely, correctly, and within the shortest period of time that the service may require.

Meet Coffee Service Tech Hope Roberts

With this in mind, I reached out to Hope Roberts, the coffee service technician for French Truck Coffee of New Orleans for some tips on how to improve communication between service techs and owners of commercial espresso equipment.

Jon: Hi Hope, how are you doing these days?

Hope: Howdy! I’m doing great. I currently have some fixes on my plate that are a little out of my comfort zone, which are my favorite ones to tackle. At this moment, I’m working on troubleshooting and repairing my first rotary water pump!

How would you generally describe what your day-to-day servicing of machines looks like? Any specific types of espresso machine (categories or brands) that you work on, so we can have a perspective on your day-to-day?

For perspective, the majority of the machines I work on are Eversys super-automatic espresso machines and Poursteady automatic pourover machines. I dabble a bit in Bunn brewers/grinders, Mahlkönig grinders, water-filtration systems, and pitcher rinsers as well. I order/stock/ inventory parts, research repairs, discuss issues with technical-support specialists, attend to emergency issues, schedule and perform preventative maintenance, educate managers and baristas on proper machine use and care, cup new coffees, and a bit more here and there. All of that is to say, as my company’s only coffee service technician, I don’t typically know what my day is going to look like until it’s already over!

Read on for Hope’s top tips for talking to service techs and for service techs talking to café operators.

Read the full user manual for your machine. This is almost always openly available on the company’s website, and if you’re having trouble finding it, I have no doubt that a representative would happily email a copy your way. This will give you a sense of confidence and basic understanding that will allow you to communicate much more comfortably with your technician. You will also likely find some great resources that will help you to better care for your machine.

When reaching out for help with a machine, send a video of the issue to your technician if at all possible, and try to include sound. This will give your technician a greater understanding of the problem at hand as well as help them determine the urgency of the issue. Sometimes, symptoms of very major issues can present in seemingly minor ways, and vice versa. If the only information I receive is “water is leaking under the machine,“ this could be anything from a loose drain line to a broken tube inside the machine. If instead I see a video of water spraying out of the bottom of the machine while no coffee is coming out of the grouphead, I know instantly that I need to visit that machine as soon as possible.

Try not to hover when a technician is working. It can absolutely be difficult to trust someone with your machine, especially when it’s your livelihood. However, please understand that as coffee technicians, we are working with high pressure systems, 200°F water, and electricity all boxed up inside a metal machine. I’ve been burned, shocked, and startled more times than I can count. Giving your technician space to work allows them to feel more comfortable while working, which helps them work faster, increases the quality of their work, and keeps everyone present safe. If your technician doesn’t give you a rundown of what they will be doing when they arrive, ask them any questions you have before they get started working and request that they check in with you every so often with updates.

Don’t lie to or withhold relevant information from your technician. We all make stupid mistakes and bad judgment calls every now and then. If you or a member of your staff accidentally (or negligently) caused damage to the machine or changed programming settings, I would much rather know off the bat than figure it out for myself after extensive troubleshooting (or leave scratching my head after I’m unable to find out the cause of the presenting issue). Being forthcoming with that type of information from the start may even save your technician from making a trip and resolve your issue faster if it is able to be fixed over the phone.

Keep an organized folder of reference pictures and videos for the primary purpose of showing what will eventually happen to machines without proper preventative maintenance and/or water filtration. I find it’s much easier to convince people that good, quality water filtration is a necessary investment after showing them a picture of a restrictor clogged with scale buildup followed by a video of what symptoms that would cause on a machine, for example.

Communicate! Make sure you are clearly giving whoever is present at the time of your fix clear details of what you will be doing, what space you will be occupying, and if you will be turning anything off or making a certain product unavailable. I find that laying out these expectations when I first arrive and am saying hello reduces stress among staff and helps them then communicate with customers that the issue is being worked on and what offerings are currently available. If you need a wide space to place your parts, ask staff what area works best so that you aren’t intruding on a high-traffic area like a drink drop-off counter. If you have to turn off the water and other things are connected to the same line, let everyone working know so that they don’t unknowingly try to use something that should not go without water (pumps tend to not like running dry).

Try not to overcomplicate your technical communication. This is one I personally struggle with a lot, as I have a passion for educating and tend to over explain fixes. What I’ve learned from this, however, is that no matter how well I explain things or how good my intentions in explaining them are, too much information can often cause people to tune out what you’re saying and miss out on the key items they need to be retaining in order to care for their machine. If you also have a tendency to over-explain, give the absolutely necessary information first and foremost and then let them know that if they’d like a more detailed explanation of the mechanisms at play, you’re more than happy to provide one.

Be honest. No café owner wants to hear that you haven’t fixed an issue that’s causing them to potentially lose out on sales, and no technician wants to be the one to deliver that news. Whether it’s due to not having the correct part available or not fully understanding the issue, I find that giving a genuine explanation of the situation helps establish trust between owner and technician. If I get stuck and have to pause a fix to call technical support, I’ll first let the owner know so that they understand why I’m not actively working on the machine and am instead using my phone. It can be difficult to admit when you don’t have an answer to something, but being open about that instead of allowing a potential misunderstanding to happen can go a long way.

Ask specific questions. If someone reaches out to you for help with a machine, they likely have more relevant information than they know they have. As a technician, you understand the intricacies of the machine and which external factors can cause issues. Your customer may not understand that things that are seemingly completely unrelated to the machine can cause problems. When did the issue start? Is there any other work being done in the café? Is there any construction going on in the area (or was there when the issue started)? You may be surprised to find out how many times a “broken coffee machine“ isn’t making coffee because someone repairing something like a sink up the water line turned off the water without notifying anyone. It happens a lot, and asking those questions over the phone before immediately heading out to the site can save everyone involved a lot of time and potential confusion.

ABOUT THE AUTHOR

Jon Ferguson (he/him) is currently residing in Siem Reap, Cambodia, focusing on writing about the world of espresso equipment and service. After nearly two decades of experience across various facets of the coffee industry, he continues to enjoy every moment of it.

Subscribe and More!

Out now: It’s the April + May 2024 issue of Barista Magazine! Read it for free with our digital edition. And for more than three years’ worth of issues, visit our digital edition archives here.

You can order a hard copy of the magazine through our online store here, or start a subscription for one year or two.

“}]]