[[{“value”:”

When BrewHub wanted more control over the coffee it served, a partnership with IMF and Roastquip made the transition to a new in-house roastery as smooth as espresso.

Since 2010, BrewHub has provided corporate workplaces with fully integrated coffee solutions. It supplies everything a workplace drinks hub might need – from coffee equipment, beans, milk, and fresh fruit to a valet service which ensures the beverage station is clean, fully stocked, and ready to welcome visitors.

At the start of 2024, BrewHub looked to level up its production of freshly roasted beans to fill its fleet of automatic coffee machines in workplaces across Australia.

“We wanted to have more control of the process, develop a deeper knowledge of the coffee, and introduce new blends and single origins,” says Craig Ellingson, BrewHub General Manager of Beans and Machines.

Working with BrewHub’s Coffee Culturalist Dom Spadaccini, Craig researched the market to find a roaster that would hit their three key criteria: consistency, automation, and sustainability. For Craig and Dom, an IMF roaster was the clear winner.

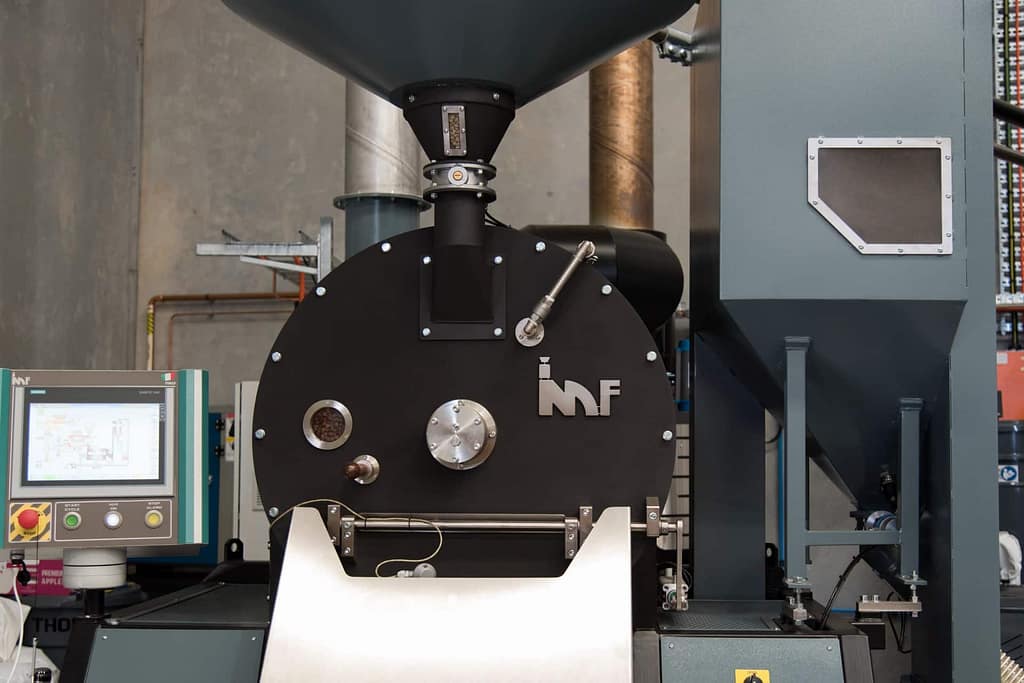

“IMF ticks all the boxes for me,” says Dom, who worked with Will Notaras of Roastquip, IMF’s Australian agent, to get an IMF RM60 60-kilogram roaster, and six two-tonne silos to Australia. Will also coordinated the installation and continues to provide after-sales support.

“I’ve worked with Will for over 15 years; we actually saw the IMF roasters together at Host Milan when they were first exhibited,” says Dom.

Consistency was the top priority for Craig and Dom as the BrewHub roastery would be producing large amounts of coffee. Within a couple of weeks of installation, the team were roasting several tonnes of coffee each week.

“Being able to maintain consistency with big volumes of coffee is tricky, but the IMF roaster can maintain a very stable temperature which produces great results,” says Dom. “We talk about the averaging out of colour and size of beans in the drum. Traditionally, it’s always been a little bit of a mystery, but this IMF machine does it better than any other I’ve worked on thanks to its one-degree temperature control.”

As a company that champions automation in all areas of its business, the BrewHub roastery needed to follow suit.

“We have a company-wide drive for efficiency, and integrating automatic machines into our workflow means we can run the roastery on far fewer people than a traditional setup,” says Craig. “This efficiency means we can pass on the reduced costs to our customers.”

Dom also believes this use of automation results in a better product.

“The great thing about the IMF RM60 is that you can still have a lot of control if you want. There’s the option to roast automatically, manually, or in a semi- automatic fashion, which allows the roaster to exercise their passion and creativity. It’s especially useful when dialling in new blends and single origins,” he says.

The equipment’s automatic functions extend to the integrated IMF silos, which reduce the amount of manual handling and heavy lifting on the roastery floor. They also enable automatic pre- or post-blending into the roaster at the touch of a button.

“We currently have two people working in the roastery, but once we’ve settled into the rhythm it could easily function with just one,” says Craig.

Many of the IMF RM60’s automatic features also contribute to its eco credentials. For Craig and Dom, finding a machine that cut workload and emissions was essential.

“It’s super efficient,” says Craig. “It uses far less gas [up to 47 per cent] than some traditional roasters, which is great from both an environmental and financial position. We power the roaster on 100 per cent green energy using a combination of rooftop solar and renewables from the grid.”

For Dom, the machine’s ability to highlight specific origin characteristics is also impressive.

“The IMF still has a traditional drum that rotates, but it’s indirect hot air heating the drum rather than a naked flame. This results in a clean heat, which we think retains a lot more of the origin’s flavour characteristics,” says Dom.

Drum speed and airflow can also be automatically adjusted throughout the machine’s 12-step profile. This means customers can choose between more conductive or convective roasting.

Craig and Dom credit Will from Roastquip with making the installation so smooth.

“Being based in Australia, importing goods from Europe is often tricky because we are so far away,” says Craig. “After-sales support was crucial to our decision and Will has been meticulous and his support fantastic.”

For more information, visit roastquip.com.au

This article appears in the April 2024 edition of BeanScene. Subscribe HERE.

“}]]