IMA Coffee details how it provides filling and sealing technologies for every type of capsule, and how IMA Group’s network of technological laboratories can be a valuable support.

IMA Coffee strives to answer the needs of the global coffee industry and engineer quality solutions to enhance the performance of its customers. To meet the needs of a rapidly evolving market, IMA Coffee’s Packaging Division covers all aspects of the packaging process, from consultancy and design to production planning and turnkey solutions, providing equipment for dosing, filling, sealing, and cartoning.

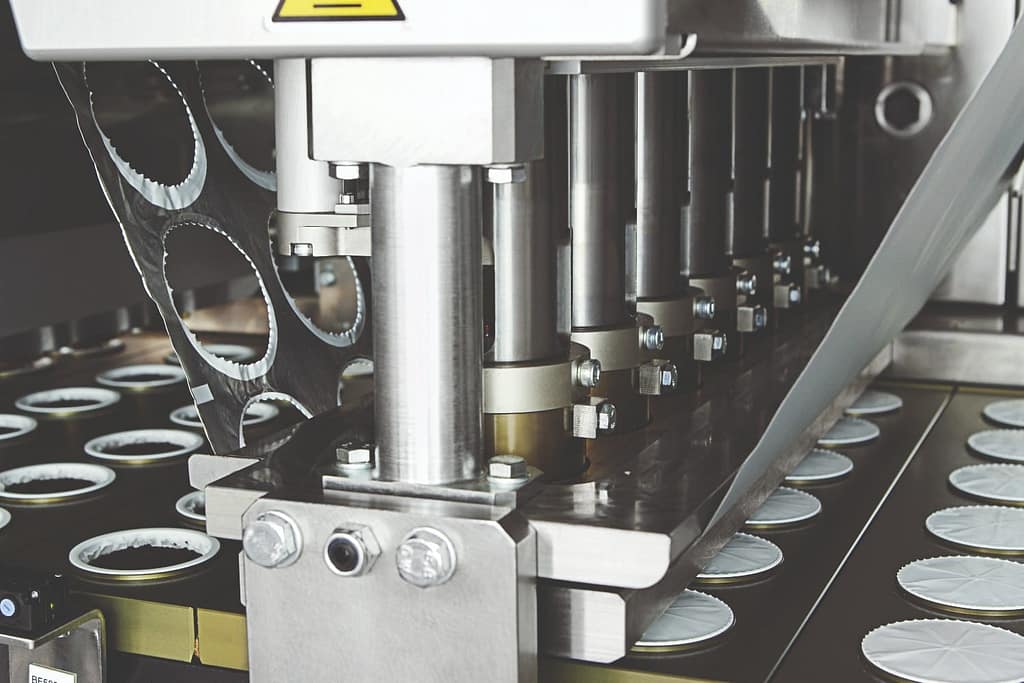

At the core of IMA Coffee’s offerings is the single-serve capsule filling equipment that can respond to market demands with high, medium, and low-speed capsule packaging solutions.

“Thanks to a high degree of automation and flexibility, every filler from the IMA Coffee portfolio can handle all types of capsules, whatever material they are made of, be it compostable materials, aluminium, or plastic,” says Giacomo Spreafico, Sales Director of IMA Coffee, Packaging Division.

Spreafico says coffee capsules are complex structures where the capsule body, lidding, and filter must be precisely designed to deliver a consistently high-quality experience. He says before the capsules even reach final consumers, it’s key that these components perform well during assembly and filling, during brewing, and on the shelf.

“Nowadays, some companies are investing in sustainable packaging techniques to offset the environmental effect of traditional plastic packaging on the planet,” he says. “Demand for compostable coffee capsules is expected to grow as customers become more health conscious and aware of negative environmental repercussions.”

Spreafico adds that companies frequently adopt aluminium material that follows a recyclability stream, combining the criteria of sustainability and reuse, and says its a “hot topic” in these times of updating packaging waste legislation.

“Some capsule manufacturers are also developing paper capsules that could represent an additional material alternative for the market,” he says.

IMA Coffee has strengthened its commitment to reduce the environmental impact along the coffee production chain in collaboration with OpenLab, IMA Group’s network of technological laboratories and testing areas dedicated to research on sustainable materials, technologies and production optimisation processes. This environmental commitment applies through adapting filling and sealing technology to the new packaging materials and testing alternative processes to preserve the resources, and minimise the packaging waste.

“OpenLab analyses new sustainable and innovative materials such as compostable, paper-based or ultra-thin film, before they are commercially available, developing projects to respond to customer needs and studying alternative processes and material specifications,” Spreafico says.

IMA Coffee, thanks to the IMA OpenLab, partnered with NatureWorks, one of the world’s leading manufacturers of low-carbon Ingeo PLA biopolymers, to accelerate the market for K-Cup compatible compostable single-serve coffee pods in North America.

“By bringing together NatureWorks’ material and application knowledge with IMA Coffee’s machinery expertise, the partnership aims to deliver a turn-key compostable coffee pod solution to the global coffee industry. This will make it simple to have a great cup of coffee and dispose of the used pod in the most sustainable way possible,” Spreafico says.

IMA Coffee’s research and development team carried out tests and used dedicated tools to simulate filter and top lid film sealing phases, and adjust parameters concurring to testing results. According to IMA Coffee, the microleakage detection testing performed at OpenLab gave encouraging results, allowing a significant step towards the coffee extraction testing phase.

“The focus on sustainable K-Cups is increasingly high in the North American market. We have sold several complete packaging lines for K-cups over the years to the biggest North American coffee producers and, thanks to IMA Coffee’s North American branch that provides excellent customer service and specialised technicians, we are ready to respond to the evolving needs of North American, which is now more receptive than ever to sustainability and innovation,” Spreafico says.

IMA Group’s OpenLab also supported the development of a paper based outer envelope for filter paper pods.

“Since 2021, IMA has followed and supported a coffee producer in Italy’s project based on the conversion of IMA Coffee’s CA3 machine to ensure the best sealing of the filter paper pod wrapping material, perfecting the sealing technology with the aim of creating a product that is completely recyclable after its separate collection as paper,” says Spreafico.

IMA OpenLab aims to build a connection between knowledge and skills from machines, packaging manufacturing, and customers.

“This is accomplished by the implementation of modern digital infrastructures, think tank spaces, environments dedicated to the generation of ideas, and the prototyping of materials. OpenLab staff are dedicated to support proofs and tests, helping customers to try new materials and test the productivity directly on the machines,” says Spreafico.

“Compatibility testing on capsules, filter, and top lid films are performed at the IMA OpenLab with the aim to identify and achieve optimum material sealing parameters and limits, as well as a suitable set up of IMA packaging machineries to handle the capsules successfully.”

This scientific approach is evident in the capsule transfer system applied to SYNKRO. This latest generation machine for coffee capsule filling and sealing combines high productivity with an efficient sealing process, especially for compostable material.

“Thanks to its innovative capsule transfer system based on the use of independent magnetic shuttles, SYNKRO guarantees high flexibility, allowing different dwell times at each operating station. This ensures that even compostable materials requiring longer sealing times can be optimally sealed without reducing the speed per cycle,” says Spreafico.

“That’s a unique solution on the market, especially in the case of compostable material. It improves shelf life of product without compromising its quality and at comparable speed with respect to standard materials.

“At HostMilano, we will be officially presenting our latest projects developed at IMA OpenLab, along with our low-medium speed filling technologies for compostable materials.”

Apart from the IMA OpenLab, Spreafico says what makes IMA Coffee different from other packaging machine manufacturers is its complementary side, IMA Petroncini.

“IMA Petroncini has more than 100 years’ experience in coffee processing. Thanks to IMA Coffee’s dualism, process and packaging travel on the same track, this results in being able to offer the customer a complete plant solution, as well as an in-depth knowledge of coffee, from the green bean to the ground powder inside the package,” he says.

“The dualism that characterises IMA Coffee converges in the IMA Coffee Lab, a coffee laboratory installed at IMA Petroncini production site in Italy covering all processing stages, from green coffee receiving and cleaning to roasting and grinding up to capsule packaging.”

Spreafico says IMA Coffee Lab technicians and consultants are always ready to find the ideal processing and packaging solutions to achieve the desired quality and taste.

“We can develop a tailor-made coffee plant examining all aspects on site at the Coffee Lab. [We] study the maximum production efficiency for the customer by carrying out trials and getting immediate answers, thus evaluating the processing stages and final coffee quality prior to commissioning the plant,” he says.

“We view each and every project as an opportunity to turn every part of the process into an advantage for coffee businesses.”

For more information, visit ima.it/coffee

This article was first published in the September/October 2023 edition of Global Coffee Report. Read more HERE.

The post How IMA Coffee adjusts for any type of capsule appeared first on Global Coffee Report.