How Mazzer has made tamping a breeze with a new machine that automatically distributes, levels, and tamps ground coffee with controlled force.

When Mazzer says it has a quality-oriented mindset, it means it. The Italian grinder manufacturer tested its latest T-Tamper distributing, levelling, and tamping machine for more than 1.2 million cycles. Only then could it be certain the device was reliable, precise, and safe to release to market.

“We strive to control the steps in the workflow of a coffee shop. That’s why we designed T-Tamper, to eliminate an additional variable which could affect the final result. No matter who is making coffee in your coffee shop, the quality in the cup will be consistent [when using the T-Tamper],” says Michele Motta, Project Engineer of T-Tamper.

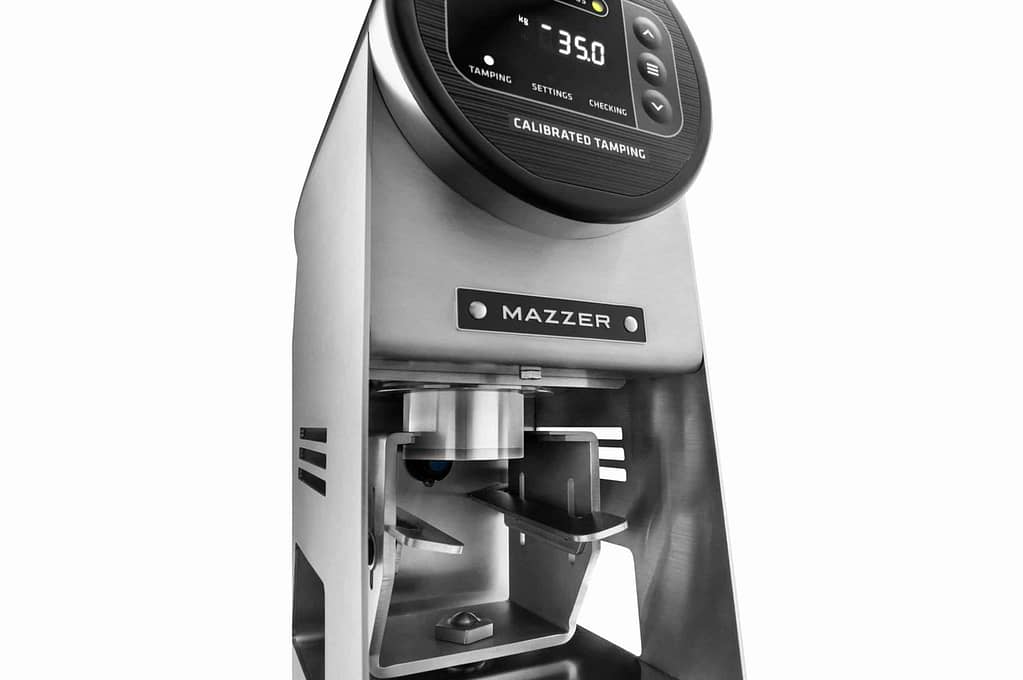

The T-Tamper is a professional barista tool, designed to obtain constant extractions, improve in-cup quality, and protect the barista’s wellbeing. It provides three tools in one, with an automatic system that distributes and levels the ground coffee in the portafilter while tamping.

“T-Tamper has been designed to guarantee the utmost precision as far as calibrating the weight distributed on the coffee puck by the tamper,” Michele says.

The T-Tamper works with any portafilter on the market, naked included. When set for the first time, the barista can choose the height from which the tamper starts to optimise work times, and avoid spillage of coffee for abundant doses.

The user can then choose between two working modes: fast with a single tamp, or precise with a double tamp. Finally, the barista selects the tamping pressure, adjusting the range from 10 to 35 kilograms.

The T-Tamper features a patented system designed to guarantee the precision as far as calibrating the weight distributed on the coffee puck.

The tamping pressure is a result of the load cell (±0.5 kilograms) that feeds the force applied on the coffee puck during tamping. Its solid and sturdy stainless-steel structure, weighing 12.5 kilograms, prevents the portafilter holder and tamping head flexing under stress to guarantee maximum parallelism. As such, the ground coffee is tamped evenly and parallel to the surface, aiding the quality of extraction.

“Once the T-Tamper is set for the first use, the barista can insert the portafilter and the machine starts automatically spinning and distributing the coffee while tamping. The design of the machine is meant to avoid coffee build-up on the tamping disc,” Michele says.

To prioritise safety, the machine has been designed with inductive cup-detecting sensors and mechanical locking systems (fingers guard) to fully protect baristas’ hands during the work cycle.

“The goal is helping baristas to improve their wellbeing and the quality in the cup. The automated coffee distribution and tamping process, with no effort for the user, prevents occupational-related diseases to the wrist, hand, and elbow,” Michele says.

He adds that the T-Tamper is easy to clean. The portafilter holder and disc can be disassembled without any tools. The compact design extends upwards rather than outwards, and at just 14 centimetres wide, can be easily accommodated on a café workbench. The machine also features statistics and a scale tare to adapt to different portafilters.

Mazzer Vice President Luigi Mazzer says the Australian community has always been strongly focused on espresso quality, not only in low-volume specialty coffee shops but high- volume cafès that strive to serve customers excellent coffee and never compromise on consistency.

“The Australian barista community has appreciated our products for more than 30 years because of their sturdiness, precision, and consistency. We think they will embrace the T-Tamper because it is conceived, designed, and produced with the same philosophy,” Luigi says.

For more information, visit Australian distributor Coffee Works Express at cwe.com.au or www.mazzer.com/en/

This article appears in the August 2023 edition of BeanScene. Subscribe HERE.