[[{“value”:”Image: Iris Group

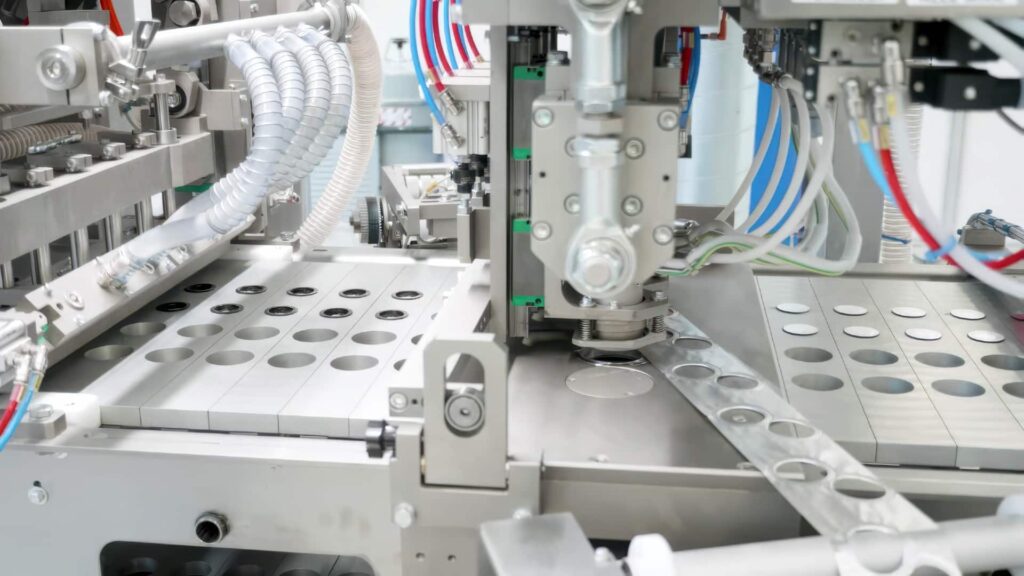

Iris Group highlights its capsule technology and how its services can deliver quality and consistency for the Asian coffee market.

Since establishing its headquarters in Singapore in 2016, Iris Group has been on a mission to become the top manufacturer in private-label coffee, tea, and soluble capsules and pods for its local markets.

Specialising in capsule production, distribution, and quality assurance, Iris Group Director Giorgio Vergano says the company’s forward-thinking solutions have helped it stand out in the sector.

“In 2016, there were very few capsule offerings in the Asian market as it was just the start of the industry, so we saw an opportunity to provide a quality-oriented service,” says Vergano.

“Since the beginning, we have had three main focuses: quality, consistency, and sustainability. We decided to implement modern technologies and have developed a research and design centre to drive innovation. We were the first company in Asia to introduce compostable biodegradable capsules.”

In recent years, the company has worked closely with speciality coffee roasters, tailoring its services and specifications to ensure the smooth transition of ground coffee into capsules while preserving the aroma and taste of the beans.

“We are always trying to break boundaries to offer our customers new solutions so we can continue to lead in the market. We work closely with our partners to study new options and work towards understanding the needs of our clients,” he says.

“That’s why we have created not one but two capsule solutions. One is our Nespresso-compatible compostable-certified capsules, and we are currently one of the only manufacturers in Asia offering a Nespresso-compatible compostable product. The other is the Dolce Gusto- compatible capsules, so two very different systems for two types of clientele.”

By focusing on catering for more than one target market, Vergano says Iris Group manufactures capsules to suit a variety of consumer requirements, beyond only the realms of coffee.

“Tea capsules, for instance, are becoming popular and the quality of capsulated tea is amazing as we can use real tea leaves. We ensure the preparation of the tea is extremely easy and consistent for the customer, which makes for a wonderful product,” he says.

Recognising the diverse nature of beverage trends, the company has also developed capsules for soluble products.

“Through our Dolce Gusto capsules, we can offer capsuling solutions for soluble products such as milk and hot chocolate. This enables us to deliver solutions to all markets and customers who are interested in a variety of drinks beyond coffee,” says Vergano.

Image: Iris Group

As well as providing a varied portfolio, Vergano says Iris Group is committed to ensuring the quality of its products remain as high as possible.

“One of the things we pay meticulous attention to is the sourcing of materials. All our materials come from Europe and are certified products of the highest quality,” he says.

“The Nespresso solution comes in two types of capsules: one is fully aluminium, like the Nespresso original, and the other is a home-compostable-certified material. The Dolce Gusto also comes in two types of capsules: one for coffee and the other for tea and soluble products.”

This focus on quality extends to the product within the capsule. To maintain the full freshness and fragrance of coffee, Iris Group has developed a specific handling process for ground coffee.

“How we handle the ingredient is a crucial part of our process. From the moment we grind the coffee or prepare the tea until the product goes inside of the capsule, it is preserved in a modified atmosphere. This ensures freshness is maintained,” says Vergano.

“Our quality control is very stringent. We have really focused on this over the years to guarantee consistency in every step, which is key to producing a reliable product and trust among customers.

“This is why we have repeat business. Every one of our clients know that from their first delivery to the most recent, we will have maintained the same standard of service.”

From the quality of the capsules to the customer service provided, Vergano emphasises how the company never compromises on its standards, which focus on providing flexibility and consistency.

“Every time we switch from one coffee to another for a customer, we clean the whole machine so there is no contamination. We do that for every client, regardless of size and quantity of production,” he says.

In terms of concentrating mainly on the Asian market, Vergano highlights the advantages of being based in Singapore.

“The main benefit of manufacturing in Singapore is its free trade agreement with most countries in the world. This means the products we make here in Singapore are free of duties when imported,” he says.

“The other advantage is being local to the Asian market. This way we can address the requests of our customers quickly and efficiently because we can understand what they need, what their working environment is, and the challenges they are presented with. Therefore, we can tailor our services to best suit them and their business.”

Since the pandemic, growth in capsule technology is something Iris Group has paid close attention to, noting a significant increase in popularity. Vergano predicts further traction in the years to come and comments on the prevailing factors.

“How things are developing is unique. If you look at the market research, capsules are becoming the most dynamic product in the coffee sector in Asia and growing the fastest,” he says.

“This is mainly due to convenience and the fact capsules provide a choice of different flavours and this is more interesting for consumers. All indications are that the coffee capsule business is growing which, for us, is really positive news.”

This article was first published in the September/October 2024 edition of Global Coffee Report. Read more HERE.

The post How Iris Group captured the Asian market appeared first on Global Coffee Report.

“}]]