[[{“value”:”Syntegon explains how it came up with a sustainable packaging solution that ensures coffee beans remain fresh and full of flavour. Image: Syntegon

Syntegon explains how it came up with a sustainable degassing valve solution that ensures coffee beans remain fresh and full of flavour.

In 2022, Canadian packaging provider Rootree had a problem. The eco-focused company had recently secured a flurry of new specialty roaster customers, but their requests to package coffee beans in fully recyclable bags was causing a bottleneck in Rootree’s production line at its site in Ontario. The culprit? Degassing valves.

There are few things as pleasing as the fragrant scent of a just-opened bag of coffee beans: it’s one of life’s small pleasures and something roasters know is an essential part of the coffee experience.

The degassing valve is a key component to locking in these aromatics, enabling the carbon dioxide that’s naturally produced by roasted beans to be released from the bag while also preventing oxygen from entering the vessel, which can make the coffee go stale and lose its precious flavour.

“As the coffee releases gas, the pressure inside the bag builds,” says Marco Weritz, Sales Engineer for Valve Applications and Valves at Syntegon.

“When it surpasses ambient air pressure, the gas inside the bag pushes a membrane within the valve outward and escapes. As soon as the pressure is equalised, the ambient air presses the membrane of the valve closed again. This prevents intake of air, protecting the volatile aromas of the coffee. Thus, valves ensure a significantly lengthened shelf life of the packaged coffee – up to 30 months.”

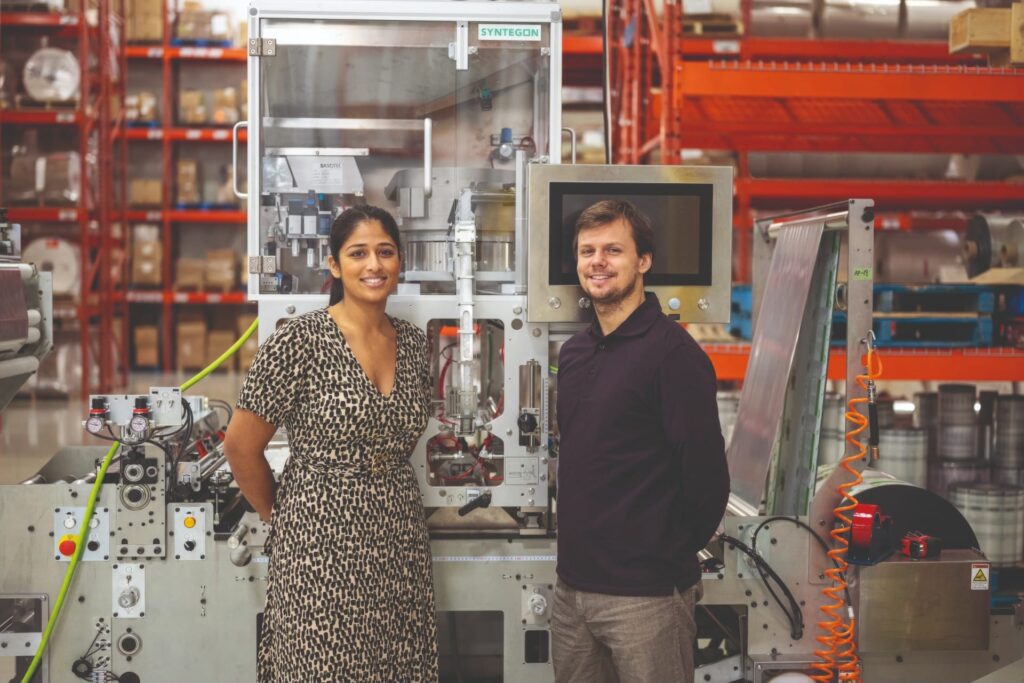

Rootree’s mostly smooth-running production line was being held up at the degassing valve stage because the valves were being applied manually. The time-consuming process meant the team were only able to yield around six to 10 ready-to-fill coffee bags each minute, slowing the whole process down considerably. Vice President of Product and Business Development Pia Simran, and President and CEO Phil St-Cyr approached Syntegon for a solution.

As a global leader in processing and packaging lines and specialising in the food industry, the German company was well placed to help Rootree release its bottleneck. It has provided valve sealing and application technology for more than 40 years, starting with technology for its own production-line machines for the coffee industry, and progressing to stand-alone application machines that can be integrated into machinery from other companies.

“We developed this technology so we could help customers reduce manual application, automate the process, and increase output,” says Weritz.

Not only did Syntegon pioneer the degassing valve technology, it was one of the only companies that could fulfil Rootree’s sustainability standards.

In a statement, Simran said: “Syntegon was the only company we came across that had a clear roadmap towards sustainable valve solutions.”

Traditional valve applicator machinery uses heat sealing to apply the valves, but this process is not compatible with the environmentally friendly mono-materials Rootree uses for its recyclable and compostable product lines. Weritz and team had already masterminded the solution to this problem: its CVA 2000 VIS Internal Valve Applicator machine, which uses ultrasonic sealing instead of heat, and is therefore compatible with mono-materials.

“The use of ultrasonic sealing means this machine can be used for almost any material,” says Weritz. “It uses high-frequency vibrations to bond the valve to the film material by generating the necessary heat for welding directly within the seal gap, without the need for external heat application.”

Image: Syntegon

While Syntegon produces complete production lines, the team were able to fit the CVA 2000 VIS as a retrofit valve applicator, seamlessly integrating the technology into Rootree’s existing Totani production line.

“We have a very good partnership with Totani, so we had a solution ready for Rootree,” adds Weritz.

“Our standard valve application machinery fits around 80 per cent of the production lines used by the coffee bag market, so we have an out-of-the-box option for most customers. If a client has a production line we don’t already have a valve applicator solution for, we can adapt our technology to create a bespoke machine that can be integrated into their setup.”

In September 2022, the CVA 2000 VIS technology was installed into Rootree’s line in just one day. Syntegon’s experienced engineers were on hand to ensure the installation went smoothly and oversee calibration and the minimal training the Rootree staff required.

Since its production line went from semi to fully automatic, Rootree has produced sustainable coffee bags faster than ever before. The CVA machine can valve up to 85 bags per minute, which can then go on to be filled, sealed, and delivered in a much shorter lead time.

In a statement, Rootree CEO St-Cyr said: “Choosing Syntegon to automate our coffee in-line valve insertion was an easy choice. It checked three boxes that are important to us at Rootree. First, a defined roadmap allows us to achieve our objective to continue developing eco-friendly products. It also helps us get products to our customers faster with consistent high quality. Finally, it improves the ease of work for our staff and operators with the seamless in-line integration and less manual labour.”

Weritz says the project was hugely successful and that the company is seeing an increasing interest in its technology as the specialty roasting sector continues to grow. The Syntegon team enjoy rising to the challenge of finding tailored, sustainable solutions for the food and coffee industries.

For more information, visit syntegon.com

The post Syntegon’s sustainable packaging solution appeared first on Global Coffee Report.

“}]]